Over the course of your decking project, choosing the right decking screws can significantly impact both the safety and longevity of your deck. This guide will provide you with all the imperative insights into Timberfix Decking Screws Outdoor Green, helping you understand their unique features and benefits. You’ll learn how these screws can enhance your project with ease, ensuring a durable and visually appealing finish that withstands the elements. Dive in to equip yourself with the knowledge needed for a successful decking installation.

Key Takeaways:

- Timberfix decking screws are specifically designed for outdoor use, providing strong and reliable performance in various weather conditions.

- The distinctive green coating on these screws not only offers aesthetic appeal but also enhances corrosion resistance, ensuring longevity for your decking project.

- These screws are engineered for easy installation, allowing DIY enthusiasts and professionals alike to complete decking projects with minimal effort.

- The unique thread design of Timberfix screws improves grip, reducing the likelihood of deck movement over time and contributing to a stable structure.

- Using Timberfix decking screws can help you achieve a cleaner finish on your decking, as they are less likely to cause splitting or damage to the timber during installation.

Understanding Timberfix Decking Screws Outdoor Green

Understanding Timberfix Decking Screws Outdoor Green

The Timberfix Decking Screws Outdoor Green are specifically designed to simplify your decking projects whilst providing reliable performance. These screws are ideal for use in wooden decking, offering a combination of strength and aesthetic appeal. Their green coating ensures that they blend seamlessly with your timber decking, making them an excellent choice for enhancing your outdoor space.

Key Features and Specifications

Little can truly compare to the lists of features these screws present:

- Corrosion-resistant coating for longevity

- Specialised thread design for enhanced grip

- Self-drilling tips for easy installation

- Available in various lengths to suit different projects

- Eco-friendly green finish, blending with your timber

This makes them a smart choice for any decking project.

Material Composition and Durability

Screws made from quality materials ensure that your decking remains adorned with reliable fixtures. The Timberfix Decking Screws are crafted from high-grade steel, providing excellent tensile strength, which means they won’t warp or break under pressure. Additionally, the protective coating not only offers protection against rust but also extends the lifespan of the screws. Decking projects often face weathering elements, and these screws’ impressive durability means you can trust your construction will stand strong and safe through various conditions, making them a dependable staple for your outdoor projects.

Types of Timberfix Decking Screws

Assuming you are commenceing on a decking project, it’s necessary to know the types of Timberfix decking screws available to you. These screws are designed to suit different tasks and environments.

| Type | Description |

| Standard | Ideal for general decking applications. |

| Composite | Perfect for composite decking materials. |

| Self-Tapping | Designed to pierce materials without pre-drilling. |

| Corrosion-Resistant | For environments exposed to moisture and weather. |

| Long-Lasting | Engineered for maximum durability and performance. |

Perceiving the right type of screw enhances the stability and longevity of your decking project.

Size and Length Options

One of the key considerations in your decking project is the size and length options available for Timberfix decking screws. Selecting the appropriate length ensures a secure grip in your decking materials.

| Length | Use Case |

| 50mm | For thin decking boards. |

| 60mm | Standard thickness boards. |

| 70mm | For layered or thick boards. |

| 80mm | For reinforced structures. |

| 90mm | Heavy-duty applications. |

Head Types and Thread Patterns

Head Types and Thread Patterns

The head types and thread patterns of Timberfix decking screws significantly influence their performance. Each design serves a specific purpose, helping you achieve the best results for your decking.

- Flat Head: Best for flush finishes.

- Pan Head: Offers more grip on the surface.

- Bugle Head: Prevents splitting in softer woods.

- Coarse Thread: Provides biting power for soft materials.

- Fine Thread: Suitable for hardwood applications.

| Screw Types | Advantages |

| Flat Countersunk Head | Applicable where a flush finish is desired. |

| Pan Head | Increases contact area for greater stability. |

| Bugle Head | Reduces risk of splitting in the decking material. |

| Coarse Thread Pattern | Great grip for less dense materials. |

| Fine Thread Pattern | Effective in dense timber applications. |

Another aspect to consider is the thread pattern, which contributes to the screw’s overall holding power. Understanding these elements ensures you choose the right screw for your decking, enhancing your project’s longevity.

- Deep Threads: For maximum grip.

- Shallow Threads: For easier driving.

- Double Threads: Reduce installation time.

- Single Threads: Better for precise applications.

- Wide Threads: Helps in softwood materials.

| Thread Pattern | Benefits |

| Deep | Offers enhanced grip and strength. |

| Shallow | Allows for more straightforward installation. |

| Double | Increases fastening speed considerably. |

| Single | Gives you precision in specific tasks. |

| Wide | Suitable for softer timber materials. |

This understanding will help you make informed choices, reinforcing your decking’s performance and appearance.

Factors to Consider Before Purchase

Factors to Consider Before Purchase

Once again, before you examine choosing Timberfix decking screws, consider several factors that can significantly impact your project. These include:

- Type of decking material

- The decking’s environmental conditions

- Quality and corrosion resistance

- Length and diameter of screws

This will ensure you make an informed decision that complements your decking project perfectly.

Decking Material Compatibility

If you’re aiming for a successful installation, the compatibility of your chosen decking material with Timberfix decking screws is vital. Different materials may require specific screw types to achieve optimal performance.

Environmental Conditions and Exposure

Consider how the environmental conditions where you live might affect your decking. Factors such as moisture, temperature fluctuations, and exposure to UV rays can influence the performance and longevity of your screws.

Decking constructed in areas with high moisture levels, for instance, demands screws with excellent corrosion resistance. Exposure to the sun can also affect your screws, as prolonged UV exposure may weaken some materials over time. If your decking is located near the coast, the salinity in the air can further accelerate corrosion. Therefore, it is imperative that you select environmentally suited screws to maximise durability and performance in your specific conditions.

Step-by-Step Installation Guide

All the information you need for a seamless Timberfix decking screw installation can be found in the following table, providing clear steps to ensure the best results.

| Step | Description |

| 1 | Prepare your materials and tools. |

| 2 | Layout the deck frames. |

| 3 | Mark your screw placements. |

| 4 | Pre-drill necessary holes. |

| 5 | Insert Timberfix screws. |

| 6 | Inspect the installation. |

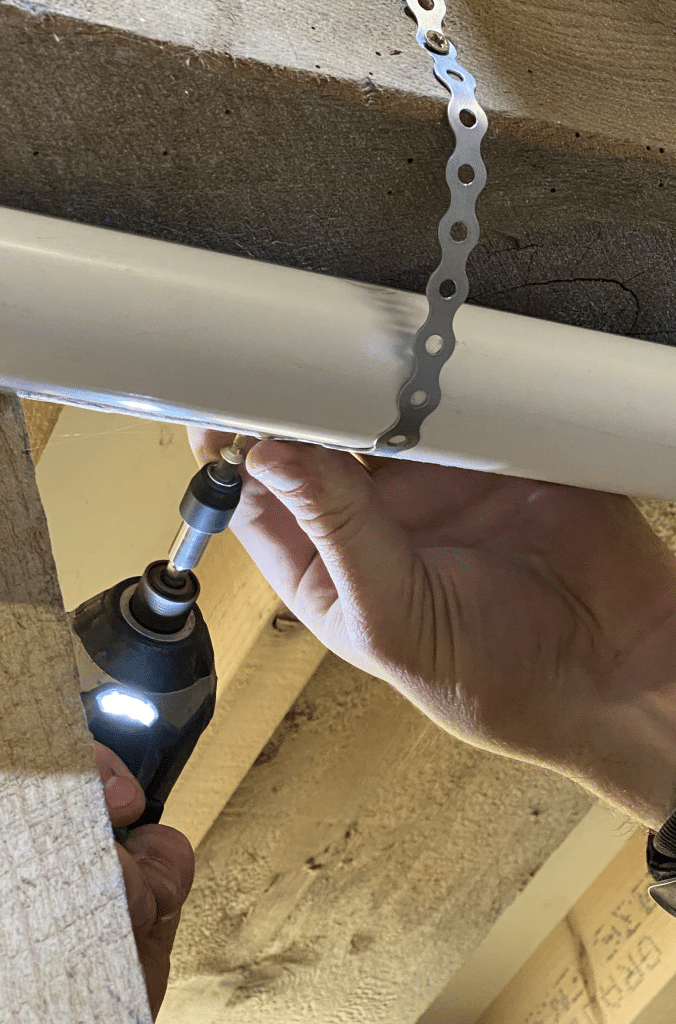

Proper Pre-drilling Techniques

The pre-drilling of holes is crucial for ensuring that your Timberfix screws are properly seated in the decking material without causing any splits. Use a drill bit that matches the screw diameter and make sure to drill to the recommended depth, which will facilitate the screw’s entry and allow for a secure fit.

Correct Spacing and Positioning

Correct Spacing and Positioning

With correct spacing and positioning, your decking will not only look great but also perform well under stress. Allow for appropriate gaps between each screw to ensure structural integrity and drainage, while also considering the expansion of timber.

Predrilling the areas for your screws contributes significantly to uniformity in spacing. Aim for a distance of approximately 300mm between each screw and place them at least 20mm from the edge of the boards to avoid any risk of splitting. This method optimises the durability and aesthetics of your decking, allowing it to withstand environmental changes while providing a polished and professional finish.

Tips for Optimal Performance

Not all screws are created equal, and achieving the best results with your Timberfix decking screws requires careful attention. Here are some tips:

- Ensure the correct pilot hole size to prevent splitting.

- Utilise the appropriate countersink depth for a flush finish.

- Employ a high-torque drill to avoid stripping.

- Store screws in a dry environment to prevent rust.

Recognising these practices will enhance the longevity and appearance of your decking project.

Maintenance and Care Guidelines

Maintenance is vital to prolong the life of your decking and screws. Regularly check for loose screws, re-tightening them as necessary. Keep the deck clean by removing debris and dirt, and consider applying a protective sealant to safeguard against moisture and UV damage.

Common Installation Mistakes to Avoid

Installation plays a significant role in the overall success of your decking project. It’s important to avoid a few common mistakes that can lead to issues down the line.

It is often overlooked that using screws that are too short can compromise the stability of your structure—ensure you select the appropriate length for your boards. Additionally, failing to pre-drill your pilot holes can result in unsightly splitting and weaken the integrity of the decking. Lastly, installing screws at an incorrect angle may not only affect the finish but also lead to inadequate fastening, compromising your decking’s safety and lifespan.

Pros and Cons of Timberfix Decking Screws

For those considering Timberfix decking screws, it’s imperative to weigh their benefits and limitations. Below, you’ll find a summary of the pros and cons to help you make an informed decision.

| Advantages | Disadvantages |

|---|---|

| Corrosion-resistant for long-lasting use | Only available in Green |

| Self-tapping design for easy installation | Not available in plastic waterproof tub |

| Designed to reduce splitting in timber | Limited availability in some regions |

| Enhanced load-bearing capacity | May not be suitable for all types of decking material |

| Flexible lengths for various decking requirements | Some users prefer traditional fasteners for aesthetic reasons |

Advantages Over Traditional Fasteners

An excellent benefit of Timberfix decking screws is their ability to provide superior holding power compared to traditional fasteners. Their unique design minimises the risk of splitting the wood while also allowing for easier installation. You will find that the self-tapping feature eliminates the need for pre-drilling, thus saving you valuable time and effort, making your decking project more efficient.

Potential Limitations and Solutions

Potential Limitations and Solutions

Limitations may arise with Timberfix decking screws, particularly regarding their cost and the need for specific tools. These fasteners can be pricier than standard screws, and if you do not have the right driver bits, installation may become cumbersome.

Plus, addressing these limitations can enhance your experience. If you invest in the specialised driver bits required for Timberfix screws, you’ll notice a significant increase in installation efficiency. While the initial cost may be higher, consider it a long-term investment in the durability and overall performance of your decking. Moreover, seeking suppliers that offer competitive pricing can mitigate the impact of cost. Understanding these factors will help you maximise the benefits of Timberfix screws in your decking project.

Summing up

Summing up, using Timberfix decking screws can significantly enhance your decking project, providing ease of installation and durable results. By selecting these outdoor green screws, you ensure optimal performance even in challenging weather conditions, ensuring your decking remains secure and visually appealing. With proper installation techniques and the right tools, you can achieve a professional finish that will enhance the overall aesthetic of your outdoor space. Invest in quality and enjoy the benefits of a beautifully constructed deck for years to come.

FAQ

Q: What are Timberfix decking screws and why are they recommended for outdoor decking projects?

A: Timberfix decking screws are specially designed screws that provide superior strength and durability for outdoor decking applications. Their unique features include a corrosion-resistant coating and a sharp, self-drilling tip, which allows for easier installation into timber without pre-drilling. These screws are recommended because they improve the longevity of your decking and ensure a secure bond, making your outdoor space more reliable and safe.

Q: Can Timberfix decking screws be used with all types of timber?

A: Yes, Timberfix decking screws are versatile and can be used with a variety of timber types, including softwoods and hardwoods. However, it is important to consider the specifications of your timber to ensure compatibility. For best results, refer to the manufacturer’s guidelines concerning the type of wood and the recommended screw size for optimal performance and secure fastening.

Q: How does using Timberfix decking screws enhance the decking project process?

A: Using Timberfix decking screws streamlines the decking project by providing an efficient installation process. Their design allows for quicker driving into the wood, reducing the time spent on the project. Additionally, their robust construction means enhanced stability and safety for the deck, ensuring that it withstands the elements without warping or loosening over time. This ultimately leads to a superior finished look and a longer-lasting deck.

Head Types and Thread Patterns

Head Types and Thread Patterns Factors to Consider Before Purchase

Factors to Consider Before Purchase Correct Spacing and Positioning

Correct Spacing and Positioning Potential Limitations and Solutions

Potential Limitations and Solutions