With a powerful and versatile tool at your disposal, SDS drills offer unmatched efficiency for a variety of drilling tasks. You will appreciate the ease of use and their ability to tackle hard materials such as concrete and masonry effortlessly. Their quick-change chuck system allows for speedy bit changes, making your work more productive. This comprehensive guide will illuminate the features, diverse applications, and distinct advantages of SDS drills, enhancing your understanding and enabling you to make informed decisions for your next project.

SDS Drills Explained Key Takeaways:

- Versatile: SDS drills are designed for a variety of materials, making them suitable for tasks ranging from masonry to concrete and even wood and metal.

- Efficiency: The rotary hammer action of SDS drills allows for faster drilling, reducing the time needed for heavy-duty tasks.

- Reduced Vibration: Many SDS models feature anti-vibration technology, which enhances user comfort and control during prolonged use.

- Quick Bit Changes: The SDS chuck system enables rapid swapping of drill bits, improving workflow and efficiency on site.

- Powerful Performance: SDS drills typically deliver significant power output, making them highly effective for heavy-duty construction and renovation tasks.

Understanding SDS Drill Types

To choose the right SDS drill, it’s vital to understand the different types available. Each type offers distinct features tailored for specific tasks and materials. Here’s a breakdown:

| SDS Plus | Designed for light to medium-duty applications, ideal for masonry and concrete. |

| SDS Max | Best for heavy-duty tasks, suitable for larger drill bits and tougher materials. |

| SDS Quick | Ensures rapid accessory changes for increased efficiency. |

| SDS Flex | Offers flexibility for both drilling and chiselling purposes. |

| SDS-Plus-BT | A bullish option for complex drilling tasks requiring adaptability. |

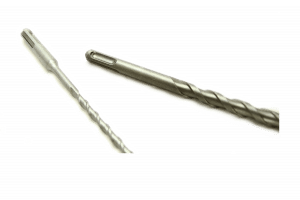

SDS Plus

The SDS Plus system is particularly beneficial for lighter tasks, such as drilling through masonry and concrete. With its 10mm shank, it allows for tool-free bit changes, making your work quicker and more efficient. This versatility makes it a favourite among DIY enthusiasts and professionals alike, ensuring that you can tackle various tasks without hassle.

SDS Max

Against the lighter options, the SDS Max system is built for durability and performance in heavy-duty applications. With a larger shank size of 18mm, this drill type accommodates bigger bits, designed to tackle the most challenging materials, such as reinforced concrete. Additionally, the SDS Max drill provides enhanced power transfer, allowing you to work with greater efficiency.

Due to its robust design, the SDS Max is often used in construction and renovation projects. You can effectively handle large diameter bits, making it perfect for significant drilling tasks like demolition and heavy equipment installations. Moreover, its mechanism ensures reduced vibration, providing better control and enhancing your safety during operation. Understanding its capabilities can significantly impact your productivity and outcomes in demanding situations.

Key Features of SDS Drills

While exploring the versatility of SDS drills, you will find several key features that enhance their performance. These include:

- Hammer function for efficient masonry drilling.

- Rotary function for standard drilling tasks.

- Ergonomic design for improved comfort during use.

- Powerful motor enabling high torque output.

- Durable construction that withstands demanding conditions.

The combination of these attributes allows for enhanced functionality, making SDS drills a reliable choice for various applications.

Hammer Action Mechanism

Among the standout features of SDS drills is the hammer action mechanism, which provides a rapid chipping motion. This technology enables the drill to deliver high-impact energy, facilitating the penetration of hard materials such as concrete and brick effectively.

Bit Exchange System

For those considering SDS drills, the bit exchange system offers immense convenience. This innovative design allows you to swap out drill bits quickly and easily without the need for additional tools, enhancing your productivity during projects.

To facilitate this swift transformation, SDS drills typically use a single-handed chuck mechanism. This means you can change the bit with just one hand, saving you valuable time on the job. Additionally, the system accommodates various bit types, enabling you to tackle a wide range of tasks, from drilling into soft woods to penetrating tough masonry. This feature not only enhances your efficiency but also significantly reduces downtime, allowing you to complete your projects faster and with greater ease.

Applications of SDS Drills

Unlike conventional drills, SDS drills offer versatility across a range of applications, making them indispensable tools for both DIY enthusiasts and professionals alike. Whether you’re tackling heavy-duty construction tasks or light home improvement projects, their ability to switch between various drilling modes enhances efficiency and effectiveness.

Concrete and Masonry Drilling

Above all, SDS drills excel in concrete and masonry drilling, thanks to their robust design and efficient mechanism. Their ability to deliver powerful blows while drilling allows you to penetrate hard materials quickly, making them ideal for tasks like installing anchors or retrofitting installations.

Wood and Metal Drilling

But you must be cautious when using SDS drills for wood and metal. Utilising the wrong drill bit can lead to splintering or warping in wood and overheating in metals, compromising the integrity of your materials. Always choose the appropriate bits, and adjust your speed settings for the best results, as this maintains precision and enhances your overall project quality.

Advantages of Using SDS Drills

Your choice of an SDS drill brings significant benefits to your drilling tasks. These tools are specifically designed for efficiency and power, which can enhance your productivity. The innovative SDS chuck system allows for quick bit changes, while their impressive torque makes them ideal for heavy-duty applications. With reduced vibration and enhanced control, you can achieve precision in even the most challenging materials, ensuring a smooth and effective drilling experience.

Efficiency and Speed

At the core of SDS drills lies their impressive efficiency and speed. These drills are engineered to tackle tough materials with minimal effort, reducing the time spent on each project. With a high impact rate, you can expect to drill through concrete and masonry swiftly and effortlessly, allowing you to complete tasks much faster than traditional methods.

Versatility in Drilling

On another note, SDS drills excel in versatility, making them suitable for a wide range of applications. You can effortlessly switch between drilling, chiselling, and even demolition tasks with the right attachments, catering to both light and heavy-duty projects. This adaptability not only saves you time and money but also permits greater flexibility in choosing tools for specific jobs. Thus, an SDS drill becomes an invaluable asset in your toolkit.

In fact, the multi-functionality of SDS drills means you can handle various tasks without needing a complete set of tools. You can easily switch from drilling holes to chiselling away material, enhancing your efficiency. The ability to use different attachments for various materials—such as wood, metal, or masonry—makes these drills an indispensable choice for any DIY enthusiast or professional tradesperson. With SDS technology, you benefit from reduced wear and tear on tools while ensuring your projects remain on schedule.

Choosing the Right SDS Drill

Keep in mind that selecting the appropriate SDS drill is necessary for achieving the best results in your projects. Consider factors such as power, weight, and drilling capacity to ensure the drill suits your specific needs, whether you’re working with masonry, wood, or metal. An SDS drill with a higher energy rating may be ideal for tougher materials, while a lighter model could be more manageable for extended use.

Considerations for Various Projects

At the outset of your project, assess the material you’ll be drilling into, as this will directly influence your choice of drill. If you’re tackling concrete or brick, opt for a drill with a heavy-duty hammer function. For lighter materials, a less powerful, versatile model may suffice, providing you with flexibility across various tasks.

Recommended Brands and Models

Right now, popular brands like Bosch, Makita, and DeWalt offer a range of SDS drills tailored for different projects and budgets. These manufacturers consistently deliver reliable, high-performance drills that cater to professional tradespeople and DIY enthusiasts alike. Choosing a reputable brand can provide peace of mind with warranties and customer support.

Considering your options, it’s important to select models that are not only powerful but also ergonomic to enhance your drilling experience. For instance, the Bosch GBH 2-26 and Makita HR2470 are noted for their durability and performance. Look for features such as anti-vibration technology, which reduces fatigue during prolonged use, ensuring that you can work efficiently and safely. Additionally, opting for a model with a reliable safety clutch can prevent accidents when encountering unexpected resistance.

Maintenance and Care for SDS Drills

Many users overlook the importance of regular maintenance for their SDS drills, yet proper care can significantly extend their lifespan and enhance performance. A well-maintained drill ensures optimal functionality, providing you with the reliable power you need for various drilling tasks.

Routine Maintenance Tips

- Regularly clean the chuck and check for debris.

- Lubricate moving parts to avoid wear and tear.

- Inspect the power cord for any signs of damage.

- Store your drill in a dry place to prevent rust.

Thou must prioritise these practices to ensure longevity and efficiency.

Troubleshooting Common Issues

Around your drilling tasks, you may encounter several common issues with your SDS drill that require immediate attention. These can range from reduced power to irregular hammer action, which can cause inefficiencies in your projects. You should always ensure that the drill bit is appropriate for the material being drilled, as using the wrong bit can lead to overheating and damage.

And, should you experience persistent issues, examine the carbon brushes for wear, as deteriorating brushes can impede your drill’s performance. Pay attention to any unusual sounds, which could indicate internal problems. If the drill fails to start, it may be an issue with the power supply or internal components. Addressing these problems quickly will prevent further damage and ensure your drill remains a reliable tool for all your DIY projects.

To wrap up

Taking this into account, understanding SDS drills allows you to make informed decisions for your drilling projects. These versatile tools offer enhanced power and efficiency, making them ideal for a variety of materials. Their unique features, such as quick bit changes and reduced vibrations, significantly ease your workload, whether you are a DIY enthusiast or a professional tradesperson. By choosing the right SDS drill, you can elevate your craftsmanship and achieve professional results with greater ease.

SDS Drills Explained FAQ

Q: What is the main advantage of using an SDS drill compared to a traditional hammer drill?

A: The primary advantage of an SDS drill lies in its specialised chuck system, which allows for quick and easy bit changes without the need for additional tools. This feature saves time and enhances efficiency during drilling tasks. Furthermore, SDS drills provide a more powerful hammer action, enabling them to penetrate tougher materials, such as concrete and masonry, with greater ease. This makes them particularly well-suited for heavy-duty applications.

Q: Can SDS drills be used for tasks other than masonry drilling?

A: Yes, SDS drills offer versatility that extends beyond just masonry drilling. While they excel at drilling into concrete, brick, and stone, many SDS drills also feature settings that allow them to function as a standard drill for wood and metal applications. With the appropriate SDS drill bit attachments, users can seamlessly switch between various materials, making them valuable tools for a wide range of projects, including DIY tasks and professional construction work.

Q: Are all SDS drills compatible with the same types of drill bits?

A: Not all SDS drills are compatible with every type of drill bit. There are different types of SDS systems, including SDS Plus, SDS Max, and SDS Quick, each designed to accommodate specific attachments. SDS Plus is the most common and suits smaller to medium-sized drilling tasks, while SDS Max is intended for heavier applications. It’s important to ensure that the chosen drill bit matches the SDS system of the drill being used to ensure optimal performance and safety during operation.