Materials play a vital role in construction, and choosing the right screws can significantly enhance your efficiency and safety. When working with various materials such as fibre cement or timber steel, it’s necessary to select screws that are specifically designed for these applications. For builders and tradespeople, using the appropriate screws means ensuring a secure fit that withstands the demands of your work, whether you’re a carpenter requiring sturdiness for framing, or a roofer needing reliable fastening that can endure harsh conditions. These screws are engineered with features that benefit your specific needs, optimising your productivity and delivering lasting results.

Fibre Cement to Timber Steel Screws Key Takeaways:

- Understanding Materials: When selecting screws, it’s necessary to consider the materials you are working with. For fibre cement, specialised screws designed to penetrate dense materials without cracking are necessary, while timber screws need to provide strong holding power without splitting the wood. Each type is engineered for specific applications to ensure optimal performance.

- Appropriate Design Features: Gash point screws offer advantages like self-drilling capabilities, making them particularly beneficial for applications in steel or other hard materials. Builders and tradespeople will find that such features can significantly enhance installation speed and reduce the need for pre-drilling, ultimately saving time on the job site.

- Compatibility with Various Trades: Carpenters and joiners will appreciate screws designed for woodwork, ensuring robust connections in furniture or structural applications. For those in construction and roofing, screws that can withstand varying weather conditions and provide long-lasting durability are of utmost importance, especially for outdoor installations.

- Ease of Use and Installation: Many screws now come with features like star drives or pre-coated finishes which prevent cam-out and enhance grip. These elements are particularly helpful for tradespeople who require reliable performance when working under challenging conditions, highlighting the importance of selecting screws that simplify their processes.

- Quality Assurance and Reliability: Opting for high-quality screws ensures that all work meets industry standards. For professionals such as plumbers and electricians, using reliable fasteners can be a matter of safety, especially when integrating different materials or systems. Builders often benefit from this assurance, knowing their projects are built to last.

Understanding Screw Types and Materials

Understanding Screw Types and Materials

For anyone involved in construction or related trades, understanding the variety of screw types and materials available is crucial. Each type serves a unique purpose and is engineered for specific applications. Below are some key points to guide you:

| Screw Type | Material |

|---|---|

| Fibre Cement Screws | Corrosion-resistant steel |

| Timber Steel Screws | High-strength steel |

| Gash Point Screws | Stainless or coated varieties |

| Construction Fasteners | Various, depending on application |

| General Fastener Tips | Material suitability |

Recognising the right screw for your project can vastly improve performance and longevity.

Fibre Cement Screws Overview

After considering the specifics of fibre cement boards, it’s vital to utilise screws designed explicitly for this purpose. Fibre cement screws are engineered with a corrosion-resistant coating, ensuring durability in challenging weather conditions. Their unique design allows for easy insertion and prevents cracking, providing a reliable fastening solution for your building projects.

Timber Steel Screws Characteristics

Timber Steel Screws Characteristics

Behind the performance of timber steel screws lies their exceptional strength and versatility. These screws are specifically crafted to penetrate hardwood and softwood materials, creating a robust connection that withstands the rigours of construction. Their thread design allows for increased grip, minimising the risk of stripping or loosening over time.

To maximise the benefits of timber steel screws in your projects, consider their applications across various trades. For carpenters, these screws facilitate the secure assembly of furniture and cabinetry. In roofing work, their high strength is indispensable for attaching battens and tiles securely. Plumbers and electricians will find timber steel screws useful for firm installations of pipes and conduit, while flooring contractors can rely on them for robust flooring frameworks. The combination of strength, ease of use, and versatility makes timber steel screws a must-have in any tradesperson’s toolkit.

Essential Screw Components

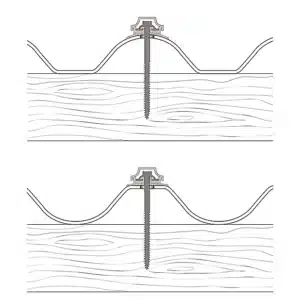

You must understand the important components of screws to select the right one for your project. Each part contributes to the overall performance of the screw, ensuring it meets the demands of various applications, be it in fibre cement or timber steel. The main components include:

| Component | Description |

| Thread Type | Determines grip and holding strength |

| Head Style | Affects driving performance and appearance |

| Drive System | Influences compatibility with tools |

| Material | Impact on durability and corrosion resistance |

| Coating | Enhances protection and performance |

Knowing these components will assist you in making an informed decision.

Thread Types and Patterns

You should consider the different thread types and patterns when choosing screws, as these can significantly influence the holding power and application. Each thread style serves its purpose:

- Fine Threads: Provide better torque and shear strength

- Coarse Threads: Ideal for soft materials to prevent stripping

- Self-tapping Threads: Eliminate the need for pre-drilling

- Double-helix Threads: Offer reduced friction during driving

- Specialty Threads: Created for specific materials or applications

Head Styles and Drive Systems

Head Styles and Drive Systems

Patterns of head styles and drive systems play a vital role in how you drive screws and the type of tools you’ll need. Different head designs, such as flat, pan, or hex, cater to specific applications, while various drive systems (like Phillips or Torx) provide different levels of grip during installation.

It is important to match the head style and drive system to your tools and the requirements of your project. For builders and tradespeople, the right head style ensures a snug fit in the material, reducing the chances of slipping, while the proper drive system offers improved control and torque application. This is particularly important for trades such as carpentry and roofing, where precision and security are non-negotiable. Indeed, choosing metal coated screws can enhance durability and resistance against corrosion, making them a preferred selection for outdoor and high-moisture environments that many trades face.

Application-Specific Selection

After evaluating your project needs, it’s important to select screws that are tailored for specific applications. Different materials and environments demand screws with unique properties to ensure optimal performance. Understanding these variables will help you make informed choices, leading to enhanced durability and efficiency in your work.

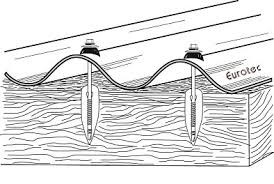

Fibre Cement Installation Requirements

Below are the key aspects to consider when selecting screws for fibre cement installations: ensure your screws are corrosion-resistant and specifically designed to handle the density of fibre cement. Look for screws with a sharp thread and a gash point tip that facilitates easy penetration, reducing the likelihood of cracking.

Timber Steel Construction Needs

Installation of screws in timber and steel requires attention to material compatibility. Use screws engineered for structural integrity, ensuring they provide the right grip without stripping or breaking. Opt for screws that feature a robust coating for weather imperviousness, which will help maintain their strength over time.

Also, selecting the right screws for timber and steel is integral to achieving strong connections that ensure safety throughout the build. Featuring high tensile strength and anti-corrosion properties, these screws are designed to endure the stress that construction environments demand. Builders and contractors will appreciate how these screws simplify the fastening process, facilitating quick installations in framing, roofing, and structural work. As a tradesperson, you rely on screws that withstand the rigours of your profession, ensuring your projects meet both aesthetic and structural standards. Whether you’re a carpenter erecting timber frames or an electrician securing conduits, the right screws will maximise performance and longevity.

Performance Factors

Keep in mind that various performance factors influence the choice of screws for your projects. Consider the following:

- Load-Bearing Capacity

- Corrosion Resistance

- Material Compatibility

- Driving Efficiency

Recognising these factors will help you select the right screws for your specific applications.

Load-Bearing Capacity

After evaluating your project’s requirements, assessing the load-bearing capacity of your chosen screws is vital. This capacity determines how much weight a screw can support, ensuring your structures remain safe and stable, especially in critical applications.

Corrosion Resistance

Corrosion Resistance

Among the considerations, corrosion resistance is important for longevity and performance, especially in outdoor environments or where exposure to moisture is prevalent. Choose screws that are designed to withstand the elements to protect your work.

Due to their robust nature, screws with enhanced corrosion-resistant coatings are ideal for tradespeople such as roofers and plumbers, who often deal with variable weather conditions and moisture exposure. Such screws significantly reduce the risk of rust and weakening over time, which can lead to structural failures and costly repairs. By utilising these specially coated screws, you ensure not only a durable finish but also added peace of mind, knowing your work stands the test of time. This is especially important when working with materials that are susceptible to deterioration.

Installation Best Practices

Your approach to screw installation can significantly impact the durability and strength of your work. Ensuring that you follow best practices not only enhances the performance of your screws but also prolongs the lifespan of the materials you’re working with. This attention to detail can make a notable difference in the quality of your projects, whether they involve fibre cement boarding or timber steel applications. Implementing these guidelines will help you achieve optimal results, delivering confidence in your craftsmanship.

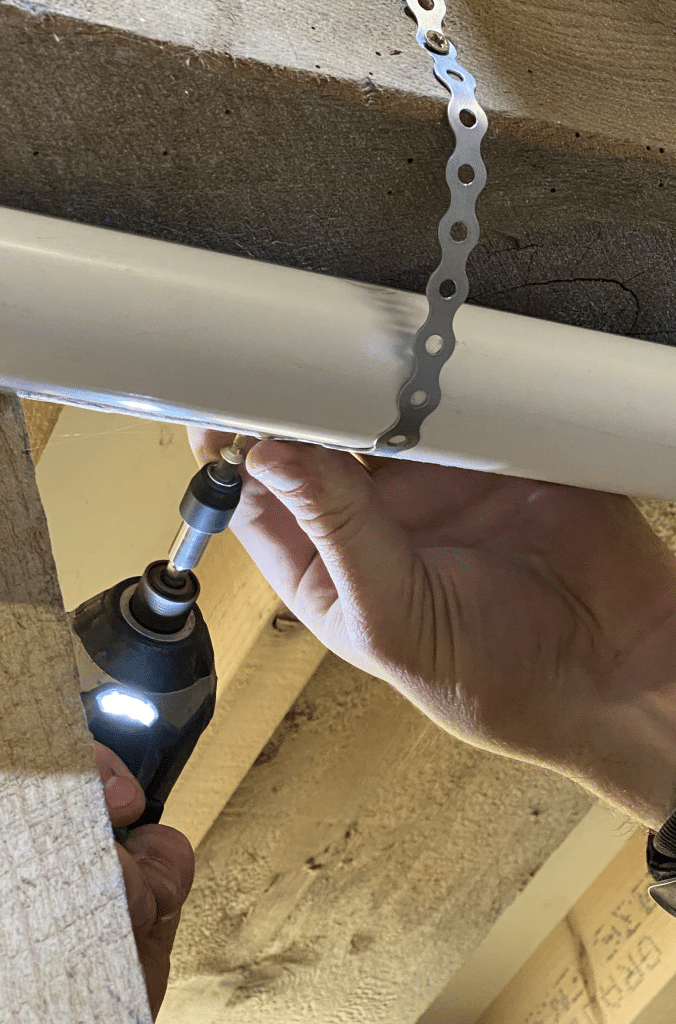

Pre-drilling Guidelines

Practices such as pre-drilling pilot holes are necessary when working with dense materials like fibre cement or hardwood. By creating these holes, you reduce the risk of material splitting and ensure a more secure fit for your screws. It’s advisable to select a drill bit that matches the screw’s diameter closely, allowing for a snug fit without excessive friction, which eases the driving process. This simple technique not only enhances the overall integrity of your assembly but also contributes to a smoother workflow on the job site.

Proper Torque and Depth Settings

An understanding of proper torque and depth settings is vital for effective screw installation. Applying the right amount of torque ensures that screws are driven firmly without damaging the material, while correct depth settings prevent protrusion and maintain a neat finish. Always consult the manufacturer’s specifications for torque requirements related to the materials in use. This meticulous attention to detail is beneficial across trades – from carpenters ensuring a flush surface in timber structures to plasterers aiming for smooth finishes in their installations.

Depth settings are particularly important in maintaining a professional appearance and functionality in your work. Overdriving screws can lead to weakened joints and expose sharp edges, which can pose safety risks on job sites. Conversely, insufficient depth results in inadequate holding strength, potentially compromising your projects. By adhering to correct torque and depth guidelines, you foster a safer working environment, ensure the longevity and reliability of your installation, and exemplify the high standards that builders and tradespeople are known for.

Common Installation Mistakes

Unlike many other elements of construction, incorrect screw installation can significantly impact the durability and effectiveness of your projects. Whether you are fastening fibre cement sheets or timber to steel, errors such as misalignment or inadequate depth can lead to structural failures. Additionally, selecting inappropriate screws for specific materials can result in poor hold and eventual detachment, so being aware of common pitfalls is vital to achieving successful results.

Material-Specific Errors

Beside general installation mistakes, there are errors tailored to specific materials that can compromise your work. For instance, when working with fibre cement, using screws not designed for this purpose can lead to premature wear or breakage. Similarly, if you’re fastening wood to steel, opting for the wrong screw type can result in inadequate grip, risking the integrity of the entire assembly.

Technical Installation Issues

Mistakes related to installation techniques can be particularly harmful. Using the wrong drill settings, failing to pre-drill in harder materials, or not adjusting for depth can result in undue stress on the screws themselves or the surrounding materials. Excessive torque can strip threads, while insufficient torque may leave screws loose, both leading to potential failures that could endanger safety and project longevity.

Due to these oversights, it’s vital that you employ the correct installation methods, taking care to account for each material’s unique properties. Applying the right amount of torque whilst using compatible screws not only enhances the security of your installation but also prolongs the life of your projects. By adhering to best practices, you can significantly reduce the likelihood of damaging your work and ensure that every component is securely fastened, supporting not just the integrity of your projects but also your reputation as a skilled tradesperson.

Final Words

Hence, selecting the right screws tailored to your specific materials, whether fibre cement or timber steel, is vital for achieving the best results in your projects. By understanding the distinct behaviours of different screws, you ensure enhanced performance and durability in every application, ultimately streamlining your work and increasing efficiency on-site.

Fibre Cement to Timber Steel Screws FAQ

Q: How do I determine which type of screw to use for fibre cement materials?

A: When deciding on screws for fibre cement, it’s imperative to look for specifically designed fibre cement screws. These screws typically feature a flat, wide head and a thread pattern optimised for drilling into dense materials. Additionally, using screws that are corrosion-resistant will enhance longevity, especially in outdoor applications. Always ensure that the screw length is appropriate for the thickness of the fibre cement board you are working with, providing sufficient grip without penetrating too deeply.

Q: What advantages do gash point screws offer in construction jobs?

A: Gash point screws are particularly beneficial for construction projects as they are designed to reduce the need for pre-drilling in many materials. The sharp cutting edges effectively penetrate and enlarge the material, allowing for quicker installation. This feature saves time and increases productivity on site, making them an ideal choice for tradespeople such as carpenters and joiners who require efficiency. Furthermore, the gash point design helps to improve the holding power of the screws, ensuring a more secure assembly.

Q: How can selecting the right screws improve the durability of my work?

A: Choosing the correct screws for your specific application is key to the durability of your finished project. Screws suited to particular materials, such as stainless steel screws for outdoor applications or self-drilling screws for metal, will perform better and resist corrosion over time. Tradespeople, including roofers and flooring contractors, benefit from using screws that are tailored to the environmental conditions and materials involved, resulting in longer-lasting constructions and lower maintenance needs.

Our product line focuses on providing high-quality screws designed specifically for the needs of builders and tradespeople. The versatility in our range—covering fibre cement, timber, and metal applications—ensures that professionals like electricians, bricklayers, and carpenters can find the suitable fixings for their varied projects.

Fibre cement screws offer distinct advantages for those involved in cladding and roofing work, featuring enhanced corrosion resistance and ease of installation. They are designed to penetrate dense materials without compromising strength. Timber screws, on the other hand, boast threaded shafts that provide excellent gripping power, ensuring stable and secure assemblies in structural work or cabinetry.

For tradespeople involved in construction, our screws recommend efficiency through their user-friendly designs, including gash point screws that eliminate pre-drilling in many cases, saving both time and effort. Such features resonate particularly well with professionals who require not only speed but also reliability in their fastening solutions.

Each screw type within our offering is tested for quality and durability, catering to the demanding environments that electricians and plumbers often work in. Using our screws, they can maintain confidence in their installations, knowing they have chosen fasteners that can withstand harsh conditions and extensive use.

To sum up, our carefully crafted screws are designed to meet the exacting standards of various trades, from construction to final finishes, allowing builders and tradespeople to perform their work with confidence and garner outstanding results.

Timber Steel Screws Characteristics

Timber Steel Screws Characteristics Head Styles and Drive Systems

Head Styles and Drive Systems Corrosion Resistance

Corrosion Resistance