Most builders and tradespeople understand the importance of selecting the right fasteners for their projects, particularly when it comes to choosing between fibre cement and timber screws. The 6.3 x 130mm screws excel in both strength and versatility, making them a reliable choice for a variety of applications, whether you are a carpenter working with timber structures or a roofer installing fibre cement boards. Their unique gash point design ensures effective penetration and reduced splitting, while their corrosion-resistant coating enhances longevity, providing you with confidence in your work’s durability. These screws truly elevate your projects by streamlining installation and ensuring a solid fit, regardless of the trade you represent.

Fibre Cement to Timber Screws Key Takeaways:

- Optimised for Diverse Materials: The 6.3 x 130mm screw is specifically designed to effectively penetrate both fibre cement and timber. This versatility makes it an ideal choice for builders who frequently work with a variety of materials in construction projects, ensuring that they can rely on a single screw type for different applications.

- Enhanced Grip and Security: With its gash point design, this screw provides superior grip and anchoring in dense materials. Builders and tradespeople can trust that once installed, the 6.3 x 130mm screw will hold robustly, reducing the risk of loosening over time, especially in applications that require long-lasting durability.

- Reduced Installation Time: The screw’s thoughtful design allows for quicker installation, making it especially beneficial for carpenters and joiners who often face tight deadlines. The efficiency gained from using a screw that can easily transition between different materials can significantly enhance productivity on the job site.

- Corrosion Resistance: The material composition of the 6.3 x 130mm screws offers excellent resistance to corrosion, which is particularly advantageous for trades like roofing and exterior work. This feature ensures that the screws maintain their integrity in various weather conditions, providing peace of mind for builders concerned about longevity.

- Precision in Application: The dimensional specification of 6.3mm in diameter and 130mm in length strikes a balance that suits multiple applications, from securing cladding to fastening structural components. This adaptability is a key asset for electricians and plumbers who may need to anchor components reliably across different substrates.

Understanding Screw Classifications

Understanding Screw Classifications

Before you choose the right screws for your project, it’s necessary to understand how screws are classified based on their materials, design, and intended use. Each type of screw serves specific applications, and familiarity with these classifications will help you make informed decisions that contribute to the robustness and longevity of your construction work.

Fibre Cement Screw Properties

Against the backdrop of harsh weather conditions, fibre cement screws are engineered with corrosion-resistant materials, offering exceptional durability. Their unique threads ensure a secure grip within fibre cement boards, preventing any loosening over time. These features make them ideal for exterior applications, where exposure to moisture and temperature variations is common.

Timber Screw Characteristics

Behind their straightforward design lies the impressive versatility of timber screws. These screws are typically crafted from strong, durable materials such as steel, which can handle the weight and stress of various construction applications. They often feature coarse threads to provide a solid hold within wooden structures, ensuring stability and structural integrity.

Properties of timber screws include their robust strength, making them suitable for critical applications in construction, roofing, and joinery. Their deep spiral threads enhance grip, helping you secure wooden frames effectively, reducing the risk of splitting. Additionally, the self-tapping feature allows for quick installation, saving you valuable time on the job. With various lengths and diameters available, these screws meet the diverse demands faced by carpenters, flooring contractors, and electricians, ensuring your projects have a reliable foundation.

Technical Specifications of 6.3 x 130mm

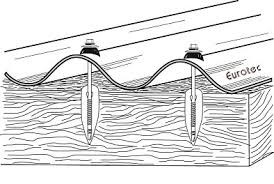

Any professional in the building trade will appreciate the precise specifications of the 6.3 x 130mm screws. Designed for excellent performance, these screws feature a robust construction that ensures maximum compatibility with both fibre cement and timber. At 130mm in length, they are suitable for deep anchoring, while the 6.3mm diameter provides the strength needed for a variety of demanding applications. Whether you’re tackling roofing, flooring, or structural projects, these screws deliver the reliability you require.

Thread Design and Pitch

Beside their sturdy build, the thread design and pitch of the 6.3 x 130mm screws plays a significant role in their effectiveness. The coarse thread allows for efficient grip in both fibre cement and timber, facilitating easier installation and reducing the risk of compromising the material integrity. You’ll find that the precise pitch helps in faster driving, which is especially beneficial when you’re working on large projects such as decking or framing.

Head Type and Drive System

Head Type and Drive System

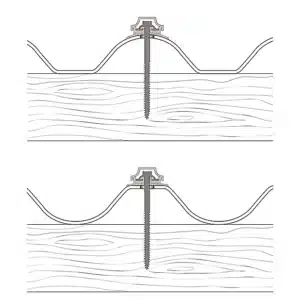

After consideration of the head type and drive system, you’ll find that the 6.3 x 130mm screws come equipped with an impressive gash point design. This unique feature ensures a clean entry into materials, reducing splitting and enhancing penetration. The head type, typically a countersunk Phillips, allows for flush installation, making it ideal for applications where aesthetics are important, such as in carpentry and decorating.

Thread engagement is key for building professionals. Strong gash point technology plays an imperative role in the installation process. The sharp, self-drilling tip enables effortless insertion, minimising the need for pre-drilling, and ensuring you can work efficiently, even in tough materials. The countersunk head provides a neat finish that is particularly advantageous for visible applications in carpentry or where you’re seeking a professional look, making your projects not only faster but also visually appealing. As a builder, you want screws that align with the demanding nature of your work, and the 6.3 x 130mm screws accomplish just that.

Performance Analysis

To understand the performance of the 6.3 x 130mm screws, it’s crucial to consider their unique design tailored for both fibre cement and timber applications. These screws provide excellent grip and stability, ensuring they withstand varying environmental conditions. The gash point serves to facilitate easy penetration through tough materials, minimising the risk of cracking in fibre cement and splitting in timber. Overall, their robust nature makes them a versatile choice for builders requiring reliable fastening solutions in diverse projects.

Load-Bearing Capacity

LoadBearing capacity is vital for ensuring that your structures remain safe and secure. The 6.3 x 130mm screws are engineered for high load-bearing performance, making them suitable for applications that demand strength, such as roofing work and flooring installations. With their unique thread design, these screws efficiently distribute weight, reducing stress on materials, which ultimately enhances the integrity of your projects.

Material Compatibility

Around the construction industry, the choice of materials can significantly impact the longevity and safety of your work. The 6.3 x 130mm screws are specifically designed to be compatible with both fibre cement and timber, allowing you to transition seamlessly between materials without compromising on quality. This compatibility is especially advantageous for builders and tradespeople who frequently work across different applications within the same project.

And the connection with builders and tradespeople is undeniable. For instance, when you are working with fibre cement, the screws’ specially designed gash point reduces the chance of material damage, while their strength ensures secure anchoring. Similarly, carpenters appreciate the ease with which these screws penetrate timber, preventing the dreaded splitting that can occur with traditional screws. This maintained reliability across trades makes the 6.3 x 130mm screws a go-to choice in your toolbelt, enhancing both efficiency and confidence in your projects.

Installation Considerations

Installation Considerations

All tradespeople must consider installation aspects when selecting screws for their projects. With the 6.3 x 130mm screws, you’ll find their design optimised for both fibre cement and timber applications. They provide the reliability needed for a wide range of tasks, ensuring effective performance whether you’re a carpenter or a flooring contractor. Proper handling and installation techniques play a significant role in achieving a successful result, making understanding these considerations vital for your work.

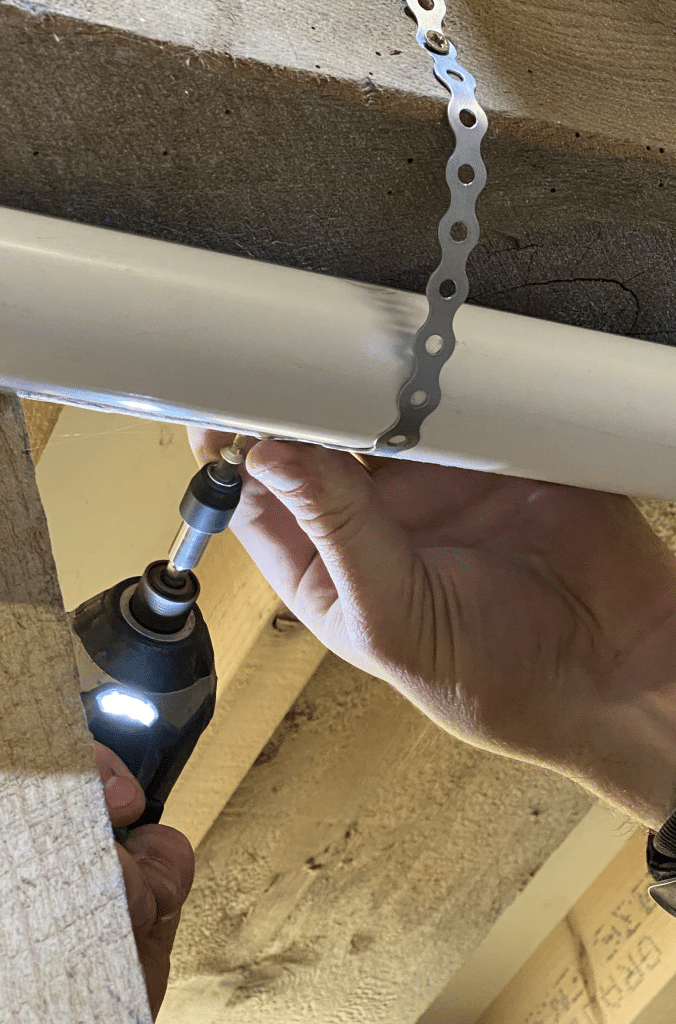

Pre-drilling Requirements

Predrilling is often recommended when working with hard materials such as fibre cement. Using the 6.3 x 130mm screws ensures you prevent splitting and achieve a cleaner finish, which is particularly beneficial for those in construction and carpentry. The precise gash point design allows for easier penetration, reducing the need for extensive pre-drilling, thus speeding up your overall installation time.

Driving Torque and Speed

Driving can make a significant difference in the efficiency and quality of your installation. Using the 6.3 x 130mm screws requires adequate torque settings on your power tools to ensure they drive effectively without stripping. Indeed, you should pay attention to the balance between speed and torque; too high a torque can lead to material damage, whereas too low may result in ineffective anchoring. These screws are designed to handle high torque applications, making them suitable for a range of trades, from bricklayers to electricians, ensuring they maintain integrity under pressure.

Durability Factors

Once again, the durability of the 6.3 x 130mm screws is evident, making them a reliable choice for various construction projects. Here are some standout features:

- High tensile strength

- Robust construction

- Long-lasting performance

Any builder or tradesperson will appreciate how these screws withstand wear and tear in demanding environments.

Corrosion Resistance

Below, you’ll discover that corrosion resistance is a key feature of the 6.3 x 130mm screws. Their special coating protects against rust and degradation caused by moisture, ensuring longevity in both outdoor and indoor applications, thus reducing the need for frequent replacements.

Environmental Performance

Environmental Performance

Durability is not only defined by strength but also by how your materials affect the environment. In terms of ecological footprint, the 6.3 x 130mm screws are designed with sustainability in mind. Factors such as their eco-friendly coatings and recyclable materials make them a smart choice for tradespeople who are committed to reducing environmental impact, while still maintaining performance. This adherence to sustainable practices enhances your project’s reputation, making you a conscientious builder. Furthermore, these screws contribute to energy efficiency and longer-lasting installations, allowing you to complete a job that aligns with modern-day environmentally responsible building practices.

Application Scenarios

Keep in mind that the 6.3 x 130mm screws excel in both fibre cement and timber applications. Whether you’re working on roofing, cladding, or panelling, their design ensures a secure fit that performs well under various conditions. These screws are specifically engineered to handle the demands of building projects, making them an ideal choice for construction professionals who require reliability and durability in their fasteners.

Recommended Usage Cases

One of the best applications for the 6.3 x 130mm screws is in the installation of fibre cement boards, which are increasingly popular for their weather resistance and aesthetic appeal. These screws provide the perfect combination of holding power and corrosion resistance, making them suitable for exterior applications. Additionally, they can seamlessly anchor into timber structures, providing versatility for carpenters and builders focused on both frames and finishes.

Limitations and Restrictions

Recommended limitations include recognising that while the 6.3 x 130mm screws excel in many applications, they may not be the best option for softer materials or heavy-duty load-bearing situations. Always assess your project’s requirements, as these screws are specifically designed for fibre cement and timber, which means using them in unsuitable materials may compromise performance.

At the same time, it’s vital to note that using these screws in environments with excessive moisture can lead to performance issues unless appropriate materials are used. They are not intended for situations where high shear forces are expected without the proper backing structure, and using them in such cases could lead to significant failures. Ensure the substrates are appropriate to maximise the benefits of these robust screws in your building projects.

Final Words

Taking this into account, when comparing fibre cement to timber screws, the 6.3 x 130mm screw demonstrates unparalleled versatility and durability that makes it stand out. Ideal for your building projects, these screws offer exceptional penetration and holding power, ensuring a robust connection whether you are working with timber or fibre cement products. This makes them invaluable to tradespeople such as carpenters and joiners, who benefit from their reliability in structural applications. With enhanced corrosion resistance, they are also a preferred choice for roofing and exterior use, guaranteeing a long-lasting finish for your work.

Fibre Cement to Timber Screws FAQ

Q: What are the key differences between fibre cement screws and timber screws?

A: The primary differences between fibre cement screws and timber screws lie in their design and application. Fibre cement screws are specifically engineered for use with dense materials like fibre cement boards. They often feature a unique thread design and a corrosion-resistant coating to withstand moisture and harsh weather conditions. In contrast, timber screws are designed for softer, more forgiving materials like wood, featuring a coarser thread for better grip. The 6.3 x 130mm fibre cement screws excel in durability and strength, making them ideal for external applications where weather resistance is needed.

Q: Why should builders choose the 6.3 x 130mm fibre cement screws for their projects?

A: Builders should choose the 6.3 x 130mm fibre cement screws due to their exceptional strength and versatility. These screws are optimised for holding power in fibre cement applications, ensuring that the structure remains secure over time. The gash point design allows for easy piercing into tough materials, reducing the risk of cracking the substrate. Additionally, the 6.3 x 130mm size offers considerable engagement, making it suitable for a wide range of thicknesses in fibre cement sheeting, thereby enhancing the overall integrity of the assembly.

Q: How do the standout features of the 6.3 x 130mm screws benefit tradespeople in their work?

A: The standout features of the 6.3 x 130mm fibre cement screws greatly benefit tradespeople by enhancing efficiency and reliability. For construction professionals, these screws provide a strong hold in challenging materials, significantly reducing the chance of failures due to environmental factors. For bricklayers and roofing contractors who often work with fibre cement sheets, the corrosion-resistant coating ensures a long-lasting finish. Plumbers and electricians can rely on these screws for fixture installations where water exposure is common, knowing that they won’t succumb to rust. Overall, these screws support various trades by offering assurance and performance in demanding conditions.

Fibre Cement to Timber Screws

The 6.3 x 130mm fibre cement screws are designed with the professional tradesperson in mind, offering unparalleled performance in building projects where fibre cement and other dense materials are involved. These screws stand out due to their robust construction and innovative design, making them an vital choice for builders and tradespeople alike.

Engineered for strength, the 6.3 x 130mm screws feature a unique gash point, allowing for precise entry into dense substrates. This reduces the likelihood of substrate cracking while providing effortless engagement. The length of 130mm ensures that these screws can penetrate enough material to create a secure hold, vital for applications like cladding, soffit boards, and roofing work. This amount of engagement brings peace of mind to carpenters and joiners as they work on both structural and aesthetic elements of a project.

The screws also benefit from a corrosion-resistant coating which is particularly advantageous for outdoor installations or areas where moisture is prevalent. This feature allows plumbers and electricians to install fixtures that withstand the elements without compromising the fastener’s integrity. For plasterers and painting professionals, the smooth finish of the screws aids in achieving a cleaner application of finishes over the top, ensuring a professional appearance.

Moreover, the 6.3 x 130mm screws allow bricklayers to secure fibre cement sheets to various structures, ensuring that their work is long-lasting and weather-resistant. The versatility of these screws means they can be used across multiple trades, appealing to a wider audience of construction professionals looking for reliability and robustness.

In the aggregate, the 6.3 x 130mm fibre cement screws connect seamlessly with builders and tradespeople by providing them with a high-quality fastening solution. Their design features not only enhance the efficiency of installing a broad range of applications but also protect against environmental factors, ultimately facilitating superior craftsmanship on every project.

Head Type and Drive System

Head Type and Drive System Installation Considerations

Installation Considerations Environmental Performance

Environmental Performance