Choosing the right fixings for your project can significantly impact the overall success and safety of your work. This guide will equip you with necessary knowledge to identify the most suitable fixings for various materials and applications. By understanding materials, load-bearing capabilities, and installation methods, you’ll be able to make informed decisions that enhance the durability of your projects. Choosing inadequate fixings can lead to serious failures and safety hazards, so it’s imperative to select the right type for your specific needs.

Choosing the Right Fixings for Your Project Key Takeaways:

- Project requirements: Consider the specific needs of your project to determine the type of fixings required.

- Material compatibility: Ensure fixings are suitable for the materials being used, such as wood, metal, or masonry.

- Load bearing capacity: Assess the weight and stress that the fixings will need to support to choose the right strength.

- Environmental factors: Factor in conditions like moisture or temperature which may affect the type of fixing to use.

- Installation method: Choose fixings that align with your installation process for ease and efficiency.

Understanding Fixing Types

For any successful project, it is necessary to identify the right fixing types. Various options are available, each suited to specific applications. Consider the following:

| Type | Description |

| Anchor Bolts | Used for securing heavy structures. |

| Screws | Ideal for joining materials together. |

| Nails | Commonly used for light construction. |

| Wall Plugs | Great for fixing items to walls. |

| Rivets | Useful in metalwork. |

Recognising the unique characteristics of each type will enable you to make informed decisions.

Overview of Fixings

Along your DIY journey, understanding the overview of fixings plays a significant role in achieving durability and safety in your projects. Each fixing type serves a purpose, catering to different materials and weights. By discerning their functions, you can enhance the effectiveness of your work.

Common Materials and Their Uses

Among the various options available, different materials contribute distinctly to the integrity of your projects. Each material is tailored for specific uses, ensuring optimal performance.

Fixing materials such as steel, plastic, and brass each present unique benefits and considerations. For instance, steel fixings offer impressive strength, making them suitable for heavy-duty applications, while plastic fixings are often lightweight and resistant to rust, ideal for indoor projects. Brass is known for its corrosion resistance, making it an excellent choice for exterior use. Balancing these qualities will significantly influence your project’s quality and lifespan.

Assessing Project Requirements

Any project begins with a thorough evaluation of your requirements, which directly influences the choice of fixings. Understanding the specific elements of your project, such as the materials you will be working with and the intended final use, is vital. Factors such as weight, stability, and the nature of the load will guide your decision-making process when selecting the right fixings to ensure safety and longevity.

Load-Bearing Considerations

On evaluating load-bearing considerations, it’s important to determine the weight your fixings need to support. Different materials exhibit varying load capacities, so always refer to manufacturer specifications. Choosing the appropriate fixing that can bear the intended load ensures structural integrity and reduces the risk of failure over time.

Environmental Factors

By taking environmental factors into account, you can avoid potential issues that arise from weather conditions and exposure to elements. Consider the following specifics:

- Humidity

- Temperature fluctuations

- Corrosion resistance

Recognizing these factors will guide you towards selecting fixings that enhance the durability and performance of your project.

This further emphasis on environmental factors is vital for the longevity of your fixings. Using materials that can withstand specific conditions, such as marine-grade stainless steel for coastal areas or galvanised fixings in damp environments, is wise. Be aware of how temperature and moisture can affect fastening materials. A poor choice might lead to rust or structural weaknesses over time. Recognizing these elements contributes to a safer and more reliable construction.

Selecting the Right Fixings

Keep in mind that selecting the right fixings is vital for ensuring the durability and security of your project. Consider the specific requirements of your task, including the materials involved, the weight of the items being fixed, and any environmental factors that could affect the fixings’ performance. Your choice of fixings should complement the project’s design while providing a strong hold that meets safety standards.

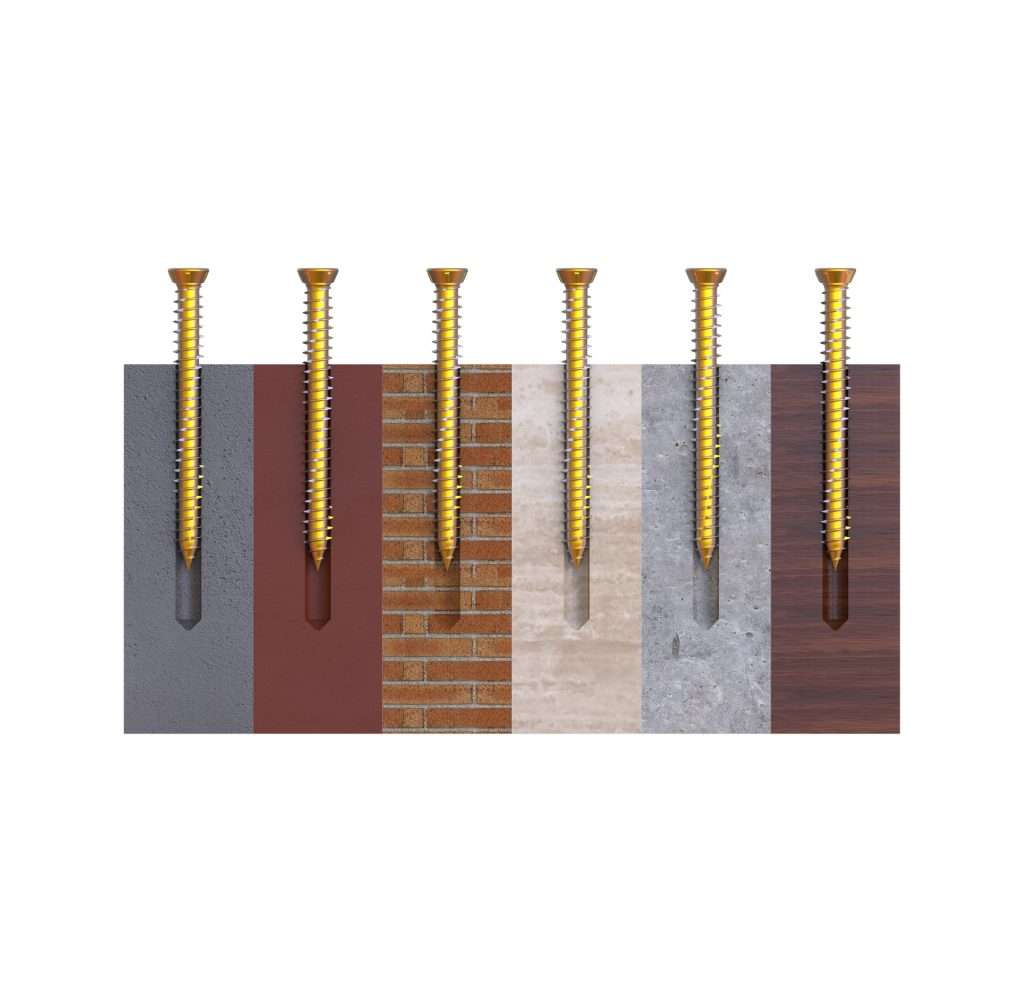

Matching Fixings to Materials

Matching the fixings to your materials is vital for achieving a successful outcome. Different materials require different types of fixings; for example, use screws for wood, while expansion plugs or anchors are ideal for masonry. It’s vital to consider the thickness and density of each material to ensure a secure fit and avoid any wear or damage.

Choosing Between Permanent and Temporary Fixings

Matching the right type of fixing to the intended use can affect both function and safety. Depending on your project, you may need to choose between permanent fixings, such as bolts or screws, which offer lasting hold, or temporary fixings, like clamps or adhesive strips, that can be removed later. Evaluating how long you need the fixings to last will help you make the best decision for your project.

Between permanent and temporary fixings, consider the nature of your project and how the fixings will contribute to its overall integrity. Permanent fixings are typically more robust and suitable for heavy-duty applications, providing a reliable solution for items that require a long-term hold. Conversely, if your project requires flexibility or adaptability, temporary fixings allow for easy adjustments or disassembly without damage. This choice can impact not only stability but also safety, so ensure you assess the demands of your situation carefully.

Tools and Techniques for Installation

After selecting the right fixings for your project, the next step is to gather the necessary tools and techniques for installation. Proper tools streamline the process and ensure that your fixings perform optimally. Using the right equipment will not only save you time but also enhance the overall quality of your work.

Essential Tools for Fixing Installation

With the right tools, your installation will be efficient and effective. At a minimum, you will need a drill, screwdriver, level, tape measure, and a variety of drill bits tailored to your chosen fixings. Having these imperative tools on hand will enable you to tackle a range of fixing tasks with confidence and precision.

Best Practices and Techniques

Below are some best practices to ensure a successful installation. Always prepare your surfaces by cleaning and ensuring they are level to obtain a secure fit. Drill pilot holes slightly smaller than your fixings to create a snug fit, reducing the risk of damaging your materials. Additionally, apply even pressure when installing fixings and utilize a torque wrench for precise tension if required.

This attention to detail will lead to a successful project and can help you avoid common pitfalls such as incorrect positioning or over-tightening, which can compromise the integrity of your fixings. Always prioritize safety by wearing appropriate protective gear and maintaining a clear workspace. Following these techniques will enhance the durability of your installation and increase your confidence in future projects.

Maintenance and Longevity

Not addressing maintenance can significantly reduce the longevity of your fixings. Regular upkeep ensures that they remain secure and functional, preventing potential failures that could compromise your project. Maintaining your chosen fixings will help you avoid costly repairs and replacements in the future.

Inspection and Maintenance Tips

Beside ensuring your fixings’ effectiveness, routine inspections can catch early signs of wear. Follow these tips for optimal maintenance:

- Check for signs of corrosion.

- Ensure tightness and stability in all fastenings.

- Inspect for any cracking or structural damage.

After implementing regular inspections, you’ll prolong the lifespan of your installations.

Factors Affecting Durability

After understanding maintenance, consider the factors influencing the durability of your fixings. Environmental conditions, material quality, and load requirements play a significant role in their lifespan. Pay attention to the following aspects:

- Moisture exposure can accelerate degradation.

- Use of low-quality materials can lead to premature failure.

- Overloading fixings can cause failure.

Assume that these factors are integral to the durability and performance of your fixings.

Plus, various elements can deepen your understanding of fixing durability. Consider the impact of temperature fluctuations, which can alter the properties of materials over time. UV exposure can also weaken certain components, while proper installation methods can enhance overall durability. It’s vital to research your specific materials and conditions before undertaking projects. Assume that informed decisions directly contribute to a successful and enduring installation.

Troubleshooting Common Issues

Once again, addressing common issues during your project can save you time and resources. Regularly reviewing your work and being proactive about problems ensures your fixings perform as intended. Identifying the source of an issue early can help you rectify it before it escalates into a larger challenge, so stay attentive and maintain a solution-oriented mindset.

Identifying Installation Errors

An effective approach to troubleshooting begins with a thorough examination of the installation process. Look for signs of improper alignment, inadequate depth, or incorrect load distribution, which can all lead to weakened fixings. Taking careful notes and reflecting on each step of installation will aid you in pinpointing potential errors.

Solutions for Common Problems

The next step is implementing strategies to address any issues you’ve identified. Ensure your fixings are compatible with the materials you are using; if not, use appropriate alternatives. Additionally, if you face problems with loose fixings, using a torque wrench can help achieve the right tension, providing increased stability.

Common issues often arise from incorrect fixing types or inadequate installation techniques. To resolve these, start by double-checking compatibility between your fixings and materials. For instance, misusing wall plugs can lead to serious structural compromises. Always ensure proper depth and alignment during installation. Regular maintenance checks can mitigate potential issues, preventing future complications and ensuring the longevity of your project. Prioritising safety and using quality materials will enhance your overall results.

Summing up

As a reminder, selecting the appropriate fixings for your project is crucial for ensuring durability and safety. You should assess the materials you’re working with, consider the load requirements, and choose fixings that match the environmental conditions. By understanding the various types available and their specific applications, you can make informed decisions that will enhance the longevity and effectiveness of your project. Following these guidelines will undoubtedly lead you to the right fixings, ensuring a successful outcome for your undertaking.

Choosing the Right Fixings for Your Project FAQ

Q: What factors should I consider when selecting fixings for my project?

A: When choosing fixings, it’s important to consider several factors including the material of the substrate (such as wood, metal, or masonry), the load requirements (how much weight the fixing will need to support), and the environmental conditions (like moisture or temperature fluctuations). Additionally, consider the type of fixture you are installing and whether the fixing will be permanent or temporary. Understanding these elements will help you select the right fixings for your specific needs.

Q: What types of fixings are available for different materials?

A: There is a variety of fixings designed for different materials. For wooden surfaces, wood screws and nails are commonly used, while for metal, self-tapping screws or rivets are appropriate. When working with masonry, expanding anchors and plugs are often the best choice. Each type of fixing has unique characteristics that make it suitable for certain materials, so it’s necessary to match the fixing to the substrate for optimal performance.

Q: How do I ensure the fixings I choose are suitable for outdoor use?

A: To ensure that your fixings are suitable for outdoor use, look for materials that are resistant to corrosion, such as stainless steel, galvanised steel, or plastic. Additionally, check that the fixings are rated for outdoor applications, as they should withstand exposure to elements like rain, sunlight, and temperature variations. Using weather-resistant coatings can also enhance durability for outdoor fixings.