It’s vital to understand how to effectively use gash point screws when working on timber and fibre cement projects to ensure strong, reliable connections. These screws are designed specifically for penetrating dense materials, making them ideal for builders and tradespeople engaged in construction, carpentry, or roofing work. Their unique gash point enables quicker driving and reduces the risk of splitting, which is vital when working with various substrates. Each trade will benefit from their superior grip and reduced stripping potential, allowing you to achieve a professional finish with ease and confidence.

Key Takeaways:

- Gash point screws are designed with a unique tip that allows for easy penetration into timber and fibre cement materials, significantly reducing the effort required for driving screws. This feature is particularly advantageous for carpenters and joiners who work with various types of wood, as it minimises the risk of splitting the material while ensuring a secure fit.

- These screws incorporate a special thread design that enhances their grip and holding power, making them ideal for construction projects. Builders can achieve reliable connections in structural assemblies, ensuring longevity and stability in their applications.

- For plasterers and painters, using gash point screws simplifies the installation process of boards and fixtures by eliminating the need for pre-drilling in many situations. This efficiency allows tradespeople to complete their tasks more quickly, which is vital in fast-paced work environments.

- Gash point screws are particularly effective in fibre cement applications, providing contractors who work with this material—such as roofing contractors and flooring specialists—the ability to fasten efficiently without damaging the boards. Their resistance to corrosion ensures durability, a significant benefit in exterior applications exposed to the elements.

- Using these screws can help reduce worker fatigue due to their straightforward application, allowing tradespeople to focus on precision and the quality of their work. This is especially beneficial for electricians and plumbers, who often need to secure multiple components or fixtures in tight spaces.

Understanding Gash Point Screws

Understanding Gash Point Screws

While selecting the right screws for your timber and fibre cement projects, understanding gash point screws is imperative. These specialised screws are designed with a unique tip that facilitates easier penetration into hard materials, reducing the risk of splitting and enhancing overall performance. Their versatility makes them ideal for a variety of construction applications, providing you with the confidence to complete your tasks efficiently and effectively.

Design and Features

Understanding gash point screws involves recognising their distinctive design elements. These screws feature a sharp, gash-shaped point that allows for a cleaner entry, minimising the need for pre-drilling in many cases. Additionally, their coarse threads provide superior grip in both timber and fibre cement, ensuring secure fastening that tradespeople depend upon.

Benefits Over Traditional Screws

At the heart of gash point screws are significant benefits when compared to traditional screws. Their innovative tip design allows for quicker installation and reduced material damage, promoting greater efficiency in your projects. Moreover, they provide enhanced holding power, which is particularly beneficial in structural applications.

Features such as the self-drilling capability and reduced splitting risk make gash point screws an advantageous choice for construction trades. Whether you’re a carpenter working with softwoods or a bricklayer utilising fibre cement boards, these screws adapt to your specific requirements. The improved thread design grants excellent grip and stability, which is vital for ensuring that your structures remain secure over time. By incorporating gash point screws into your toolkit, you can elevate the quality and durability of your work, making them an indispensable asset for any trade involved in construction and installation projects.

Preparation and Material Considerations

Some careful preparation is vital before using gash point screws in your timber and fibre cement projects. Assess the materials to ensure compatibility, as the choice of substrate can significantly impact the performance of these screws. Properly preparing your workspace will enhance efficiency and deliver better results, allowing you to maximise the benefits that gash point screws provide.

Timber Type Selection

Material selection is important when working with gash point screws, particularly with timber. You should choose hardwood for its density and durability, while softwoods can also work effectively, depending on the application. Be mindful of the moisture content in your timber, as well-dried wood will yield stronger and more reliable results. When choosing the right wood screws, it’s essential to consider both the type of wood and the screw’s design for optimal performance. A proper fit between the screw and wood can prevent splitting and ensure a secure hold. Additionally, always match the screw length to the thickness of your lumber to achieve the best results.

Fibre Cement Requirements

Fibre Cement Requirements

Beside timber, understanding the requirements for fibre cement is vital for achieving optimal results. This material can be challenging to work with, so ensure you use specific gash point screws designed for fibre cement applications. These screws have a sharper tip that facilitates easy penetration and reduces the risk of cracking the substrate. Additionally, pre-drilling may be necessary in some cases to further prevent damage to the material. Using high-quality gash point steel screws ensures a secure hold and enhances the overall durability of the installation. Always follow manufacturer guidelines to achieve the best performance and longevity for your fibre cement projects. Consider the weight and thickness of your fibre cement boards, as these factors can influence how to choose the right screws for your application. It’s important to select screws that not only fit the material but also provide the necessary support for the specific project requirements. Additionally, consulting with professionals or experienced installers can provide valuable insights into achieving the best results.

Another important factor when working with fibre cement is ensuring that your screws are of high corrosion resistance. This is particularly relevant in environments where moisture is prevalent, as standard screws might rust and compromise the integrity of your installation. Using gash point screws provides you with a reliable fastening solution, enhancing both the durability of your project and the overall safety for trades such as roofing contractors, electricians, and plumbers. By selecting the right product, you can prevent issues related to expansion and contraction, ensuring that your work stands the test of time.

Essential Tools and Equipment

After selecting the right gash point screws for your timber and fibre cement projects, you’ll need the appropriate tools to optimise your installation. Ensure you have a high-quality drill, suitable bits, and a portable workbench for stability. Additionally, a screw gauge will help you accurately measure your screws, improving your efficiency and accuracy. Protective gear should also be considered to ensure your safety while working.

Recommended Drill Types

With the right drill, you can significantly enhance the performance of gash point screws. Ideally, opt for a variable speed cordless drill that offers torque settings for precise control. Consider the following options:

- Brushless drills for prolonged battery life

- Percussion drills for heavier applications

- Compact drills for tight spaces

- Right-angle drills for awkward angles

- Impact drivers for enhanced torque

Knowing which drill type best suits your needs can drastically improve your project outcomes.

Pre-drilling Guidelines

Between working with timber and fibre cement, pre-drilling can ensure a successful screw installation. When using gash point screws, it’s advisable to pre-drill to prevent splitting or cracking, especially in harder materials. Ensure the diameter of the pre-drilled hole is slightly smaller than the screw’s shank for a secure fit. Additionally, when working with materials like metal or when using ferrotek steel self drilling screws, pre-drilling is not usually necessary since these screws are designed to create their own hole while maintaining a strong hold. However, for best results, ensure that the surface is clean and free of debris to optimize the screw’s performance. Proper installation techniques not only enhance durability but also reduce the risk of damage to the materials being joined.

Essential to your installation process, pre-drilling helps to enhance accuracy and prevent material damage while using gash point screws. When working with timber, a slightly smaller hole prevents the wood from splitting, preserving its structural integrity. In the case of fibre cement, pre-drilling provides a clean entry point, avoiding cracking and enabling better thread engagement. It’s important to select the right drill bit for both materials to ensure optimal results, making your projects safer and more efficient.

Installation Best Practices

Despite their advantages, using gash point screws effectively requires attention to detail. Following some installation best practices can greatly enhance performance and durability. Ensure that your screws are fully driven into the material to secure the joint, and consider pre-drilling when working with harder materials. This not only optimises the screws’ holding power but also reduces the risk of splitting timber or damaging fibre cement. Proper selection of screw length relative to the thickness of your materials will significantly impact the integrity of your construction.

Proper Screw Positioning

Above all, correct screw positioning is crucial for achieving maximum strength. Position screws at least 2-3 cm from the edges of timber and in a staggered formation when fastening multiple screws. This approach helps distribute stress more evenly and reduces the likelihood of splitting. Make use of markings or guides to ensure a uniform pattern, especially in larger constructions. A precise placement will enhance the overall stability and longevity of your project.

Torque and Speed Control

Torque and Speed Control

Best results often come from careful torque and speed control during installation. Using a power tool with adjustable settings, ensure that you apply consistent torque to each screw. This prevents over-tightening, which can compromise the integrity of your materials or lead to screw breakage.

Torque is vital for maintaining the balance between adequate fastening and material preservation. Applying too much torque can lead to material failure or even tool damage, while insufficient torque may result in loosened joints over time. By controlling your speed, you can also ensure that screws are driven in smoothly and uniformly, which diminishes the risk of splits and cracks in both timber and fibre cement. Paying close attention to torque and speed will not only enhance your work quality but also improve overall project efficiency, making your builds more reliable and sturdy.

Gash point screws are specifically designed to meet the needs of tradespeople, including carpenters and builders, who rely on superior performance in timber and fibre cement applications. Their sharp gash points enable speedy penetration, reducing the need for pre-drilling, and ultimately saving you time on the job. With a robust construction, these screws are ideal for securing frameworks, flooring, and roofing elements, ensuring strong joints that withstand the test of time. Whether you’re tackling construction jobs or working on intricate carpentry projects, investing in high-quality gash point screws can streamline your workflow and enhance the durability of your builds. Their versatility makes them suitable for various trades, empowering you to tackle diverse tasks with confidence.

Common Application Scenarios

All tradespeople can benefit from using gash point screws, particularly in scenarios requiring strong and dependable fastening solutions. These screws are specifically designed for timber and fibre cement projects, making them an imperative choice for carpenters, builders, and construction professionals. Whether you are constructing a new deck or installing fibre cement boards, these screws offer unparalleled performance and reliability, ensuring that your work withstands the test of time.

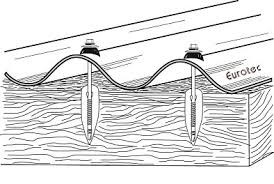

Timber Decking Projects

Between the demanding conditions of outdoor environments and the need for durability, gash point screws are ideal for timber decking projects. These screws feature a sharp point that penetrates the wood easily, allowing you to secure deck boards firmly without splitting the timber. This not only saves you time but also enhances the structural integrity of your decking.

Fibre Cement Board Installation

To ensure a secure and lasting installation of fibre cement boards, gash point screws excel in penetrating tough materials quickly and efficiently. Their design allows for precise fastening while reducing the risk of material damage, which is imperative in achieving a smooth finish and long-lasting result.

The installation of fibre cement boards often requires careful attention to detail, as improper fastening can lead to issues like cracking or water infiltration. Gash point screws provide a robust solution, capable of coping with the density of fibre cement without requiring pre-drilling. This not only expedites your workflow but also enhances the stability of the boards in various weather conditions, making them perfect for exterior applications. With their high resistance to corrosion, these screws are particularly advantageous for builders working on projects subject to moisture or harsh elements, ensuring your work remains effective over time.

Troubleshooting and Maintenance

Troubleshooting and Maintenance

Many users encounter challenges when working with gash point screws, yet simple troubleshooting can often resolve these issues. Inspect your screws regularly for signs of wear or damage, ensuring that their sharp points remain effective for driving into materials. Keeping your tools well-maintained and properly calibrated is equally vital in achieving optimal results. Additionally, if you experience difficulties with screw engagement, consider adjusting your technique or the type of screws you are using to ensure compatibility with your specific project materials.

Avoiding Common Mistakes

Below are some common pitfalls to avoid when using gash point screws:

- Over-tightening can strip the screw head or damage the material.

- Choosing the wrong size may lead to inadequate hold.

- Neglecting pilot holes in dense materials can cause splitting.

- Improper storage can lead to rusting or tip deterioration.

Recognizing these mistakes will help you achieve superior results in your projects.

Long-term Performance Tips

Around your job site, maintaining gash point screws is vital for their longevity. Proper usage techniques, such as selecting the appropriate screw length and material for your specific application, can significantly enhance performance. Ensure you apply a consistent torque to avoid stripping and damaging your work surfaces. Additionally, consider using a protective coating to prevent corrosion, especially in outdoor applications.

- Regular inspections help identify any wear on screws before they fail.

- Using quality tools preserves screw integrity during installation.

- Proper storage ensures screws remain in optimal condition.

Recognizing the importance of these practices extends the life of your fasteners and improves your overall project quality.

Common challenges that tradespeople encounter revolve around the diverse applications of gash point screws in their projects. Whether you’re a carpenter working on framing or a flooring contractor installing subflooring, these screws provide the necessary grip and penetration needed in both timber and fibre cement applications. With their unique gash point design, they facilitate easy driving and reduce the risk of splitting materials, making them a favourite among builders. Their versatility means you can confidently use them across various tasks, enhancing assembly speed and durability, ultimately contributing to a successful build. Prioritising quality in your fasteners will result in fewer callbacks and more satisfied customers, reinforcing your reputation as a reliable tradesperson.

Conclusion

As a reminder, utilising gash point screws effectively can greatly enhance your timber and fibre cement projects. Focus on selecting the right length and gauge for your materials, pre-drilling when necessary, and applying consistent pressure for a secure fit. Proper technique, coupled with the unique design of gash point screws, ensures smooth insertion and reduced material splitting, streamlining your workflow. By refining your approach, you can achieve stronger, more reliable results in your construction tasks.

Gash Point Screws in Timber FAQ

Q: What are the advantages of using gash point screws in timber projects?

A: Gash point screws are designed specifically for timber, featuring sharpened tips that allow for easier penetration into wood materials. Their unique gash point design reduces splitting of the timber, ensuring a cleaner finish. Additionally, these screws typically have a higher tensile strength, providing enhanced holding power, which is particularly beneficial for carpenters and joiners who require durable and long-lasting fastenings in their projects. Using gash point screws can significantly increase the efficiency of the installation process, reducing both time and effort for builders.

Q: How do gash point screws perform in fibre cement applications?

A: Gash point screws perform exceptionally well in fibre cement applications due to their specially designed threads, which create minimal friction during installation. This is particularly advantageous for trades such as roofing contractors and plasterers, who often work with fibre cement boards. The gash point aids in swiftly breaking through the material’s surface, allowing for faster installation while minimizing the risk of cracking or damage to the fibre cement. These screws also provide reliable anchoring, which is imperative for maintaining the integrity of fibre cement structures.

Q: Are gash point screws suitable for different types of construction projects?

A: Yes, gash point screws are highly versatile and can be used across a range of construction projects. Builders, bricklayers, and electricians can benefit from their reliable performance in both timber and fibre cement applications. The unique design of these screws allows for improved performance in both soft and hard materials, making them an excellent choice for a variety of fastening needs. Their adaptability ensures that tradespeople can rely on gash point screws for both structural applications and detailed finishing work.

Gash point screws are an innovative solution tailored for the demands of the building industry, providing the ideal fastening option for timber and fibre cement projects. These screws are engineered with a sharp, gash point tip that ensures effortless penetration into materials, making them an attractive choice for builders, joiners, and carpenters looking to enhance their efficiency and precision on the job.

The unique design not only facilitates easy installation but also reduces the likelihood of material splitting, which is a common concern when fastening timber. With their strong, robust composition, gash point screws boast exceptional holding power, providing peace of mind for tradespeople who demand reliability in their fasteners.

For plumbers and electricians working in environments that require consistent and secure fixtures, gash point screws offer the durability to withstand various conditions, ensuring that their fixtures maintain integrity over time. The versatility of these screws allows them to be used effectively in a range of applications, from framing and flooring work to more intricate jobs executed by painters and decorators.

The adaptation of gash point screws in fibre cement projects is particularly noteworthy, where their threads are specifically designed to minimize friction and reduce the risk of cracking or damage during installation. Roofing contractors and plasterers, in particular, appreciate the suitability of these screws for use in fibre cement boards, benefitting from faster installation times without sacrificing performance.

Overall, gash point screws are a valuable addition to the toolkit of any tradesperson, providing reliability, durability, and simplicity in fastening across a multitude of building and construction applications.

Understanding Gash Point Screws

Understanding Gash Point Screws Fibre Cement Requirements

Fibre Cement Requirements Torque and Speed Control

Torque and Speed Control Troubleshooting and Maintenance

Troubleshooting and Maintenance